Let us keep the magnetometer aside for now. A dedicated explanation of how that works will come on a separate blog post. If we focus on solar cells, you may remember that we talked about measuring their efficiency a while back.

The famous Current-Voltage characteristic you heard about back then, is exactly what we want to obtain for each of our devices while they fly. Those characteristic curves are made by couples of Current and Voltage values, collected -for example- by applying Voltage X (in water analogy, this was the pressure), and reading the current Y that "comes out" of the system (or the flow of water through the pipe).

Sounds easy enough, but it is actually quite complicated to do it, if you have to design the whole circuit...

This is where Steven (forgot about him?) came to save us.

He is designing the measurement instrumentation for us. Roughly, this means that he has programmed a little computer chip to send specific signals to a net of amplifiers, resistors and capacitors. These signals, just like the whole circuit components web, are finely tuned to make sure that the correct Voltage is selected, and that the readout of the Current is accurate and within the limits that the computer chip can withstand without breaking.

Why do we have to be so precise?

Home-built dedicated circuits are normally cheaper than the fancy equipment we would have in a laboratory. That's why we can actually afford to mount them on the balloon and let them crash -maybe very harshly- at the end of the ride. Lab tools are also very heavy and require way too much power to operate... Really not fit for flying with the BEXUS!

They are of course designed to handle a very large variety of "situations" and to be used for many different applications.

That's one downside of our cheaper setup: it does not have such flexibility. We have to build the safety measures ourselves, to make sure we do not let too much current in the chip, for example, or to avoid overheating amplifiers.

But calculating the needed components for the wanted ranges of operation is not all!

You might remember that we want to test a few different kinds of solar cells... As a total, we are going to mount photovoltaic devices from six different materials on our BEXUS gondola!

What does this translate to?

Six times the requirements for operational ranges, six different layouts for the pins with which we need to apply the Voltage and read the Currents, and a whole lot of cables and connections to take care of!

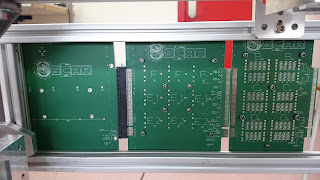

But Steven fixed this, as well: he packed all the cables in some extremely pretty Printed Circuit Boards, which are like thick sheets of copper and insulators, and contain the various connections within them, on separate layers. They also have a shielding copper plate, to avoid signal distortion.

Can you believe that there are the equivalent of 149 cables in these green sheets?

OSCAR's logo is there, you will notice.

OSCAR's logo is there, you will notice.This is because our engineers are actually artists at heart ;-)

Now, the work is far from done... the PCBs contain the connections, but they don't have the contacts for the devices on them, for example. And attaching all those tiny pins is quite tedious, besides being potentially dangerous!

PS: have you checked out the short musical version of this story yet? It's on our Youtube channel!

Geen opmerkingen:

Een reactie posten